HUAWIN

CNC THREAD GRINDING MACHINE WG2000

CNC THREAD GRINDING MACHINE WG2000

CNC THREAD GRINDING MACHINE WG2000

■ Designed with a square bed, providing excellent overall rigidity.

■ Features a dialogue-based input screen, making operation simple.

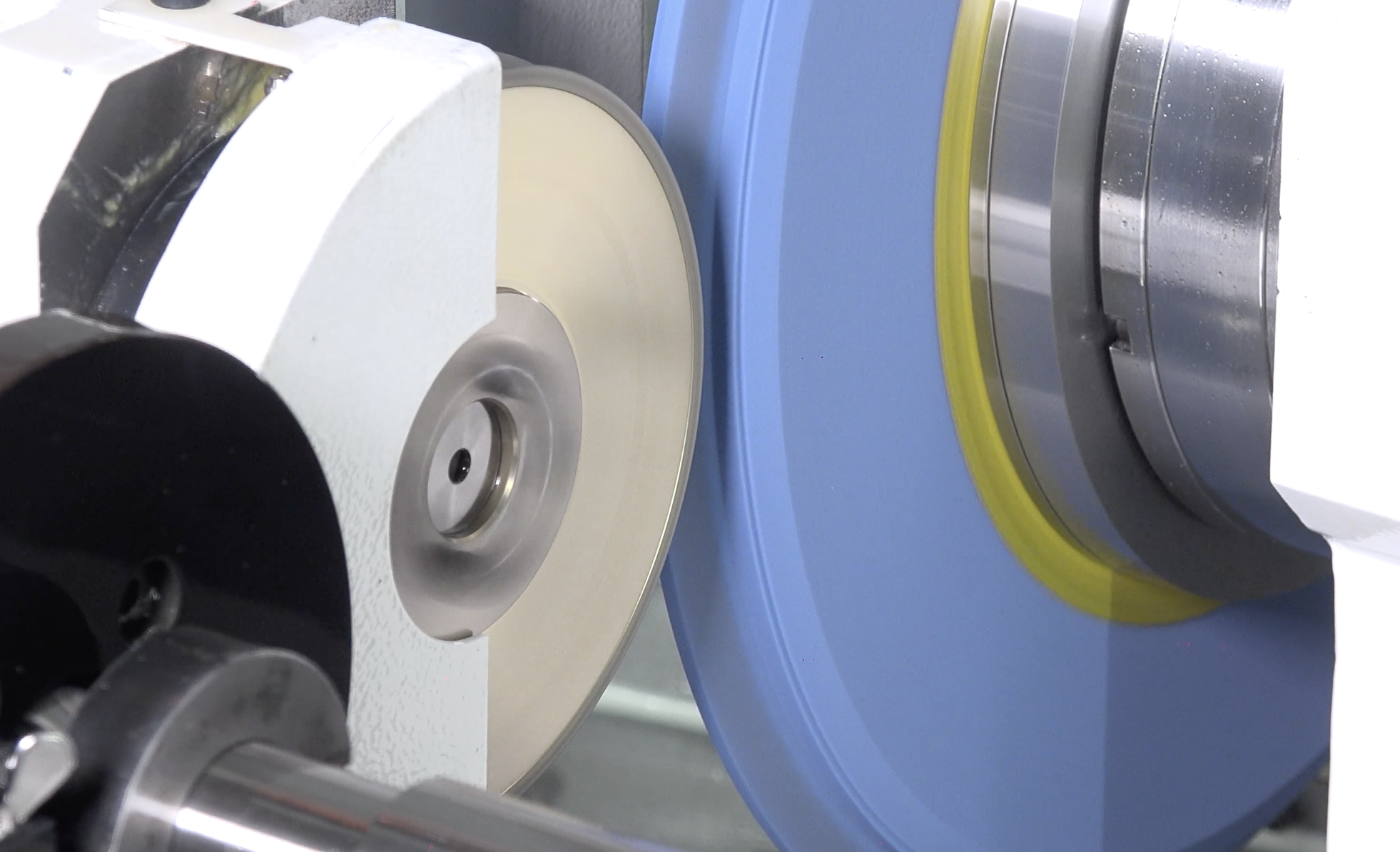

■ Equipped with a disk-type dressing device, ensuring stable workpiece accuracy.

■ The workpiece axis adopts DD motor design, eliminating mechanical backlash errors and improving positioning accuracy.

■ X-axis and Z-axis employ linear motor design, eliminating the backlash errors typical of ball screw systems, enhancing positioning accuracy and processing efficiency.

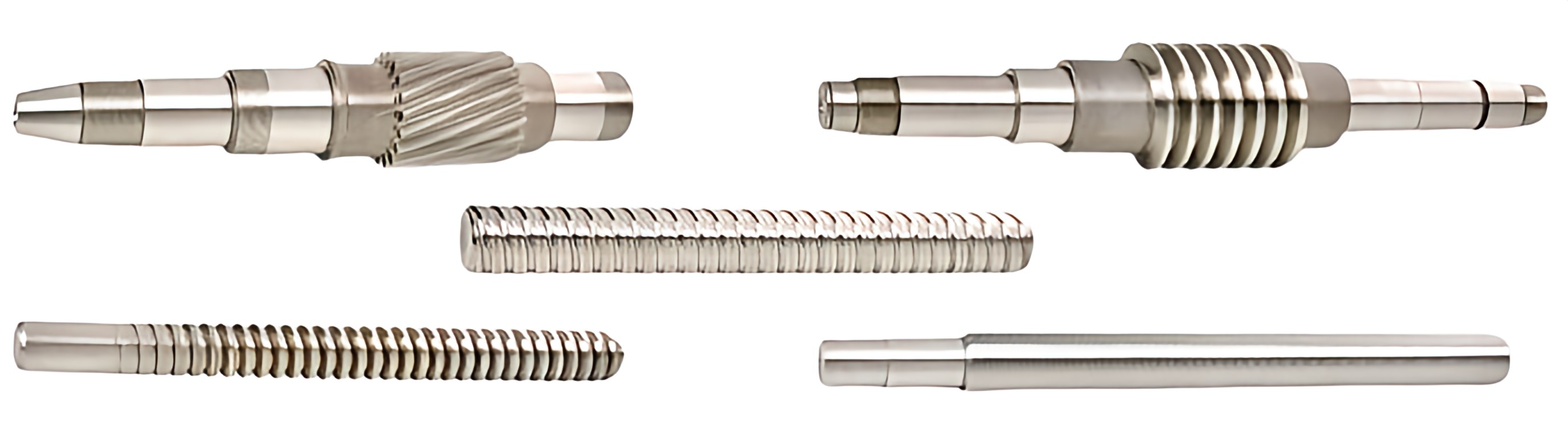

■ Capable of grinding: ball screw, roller screw, worm, thread, air compressor rotors, and more.

■ Features a dialogue-based input screen, making operation simple.

■ Equipped with a disk-type dressing device, ensuring stable workpiece accuracy.

■ The workpiece axis adopts DD motor design, eliminating mechanical backlash errors and improving positioning accuracy.

■ X-axis and Z-axis employ linear motor design, eliminating the backlash errors typical of ball screw systems, enhancing positioning accuracy and processing efficiency.

■ Capable of grinding: ball screw, roller screw, worm, thread, air compressor rotors, and more.

| Item | Specification | |

|---|---|---|

| Workpiece | ||

| Max. Workpiece diameter | Φ300 mm | |

| Min. Workpiece diameter | Φ10 mm | |

| Max. Module | 12.5 mm | |

| Number of Thread | 1~99 | |

| Pressure angle | 5°~45° | |

| Max.load(including fixture) | 120 kg | |

| Travel | ||

| X-axis (Linear motor) | 290 mm | |

| Z-axis (Linear motor) | 800 mm | |

| A-axis Helix angleb range | ±40° | |

| C-axis rotation angle ( DD motor) | 360° | |

| C-axis Max. torque | 1300 N.m | |

| Center distance | 50~1000 mm | |

| Spindle | ||

| Spindle Power | 16 kW | |

| Max. Spindle speed | 4000 rpm | |

| Others | ||

| Power requirement | <20 KVA | |

| Air consumption | 30 L/min | |

| Air Pressure | 0.5 Mpa | |

| Machine Dimensions (LxWxH ) | 2200 X 2600 X 2000 mm | |

| Machine Weight | 8000 kg | |

English

English 繁體中文

繁體中文 Japan

Japan France

France Germany

Germany Italy

Italy